Brewery

Mash Tun

Mash Tun is a brewhouse vessel used for mixing the ground malt (grist) with temperature-controlled water. This is called “mashing” and the porridge-like result is called the “mash.” See mash and mashing.

Lauter Tun

Lauter Tun is a vessel for separating the wort from the solids of the mash. See grant, lautering, mashing, and sparging. A lauter tun works much like a large sieve. It normally has a slotted, perforated floor, also called a false bottom, which holds the spent milled grains, while allowing the wort to filter through the grain bed and collect in the space beneath; the wort then runs to the brew kettle.

Want to discuss Your next project?

Wort Kettle

Wort Kettle, the vessel in which beer wort is boiled with hops. Over time these were refined to include furnaces designed to concentrate heat onto the bottom boiling surfaces

Whirlpool

Whirlpool is a common method used in commercial breweries to separate hop pellets and trub from wort after the wort boil. Instead of pumping the wort after boiling, use a big spoon to stir persistently in a circular motion in one direction. This will generate a mini-whirlpool.

Boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

Malt Mill

Milling is the physical crushing of malt kernels into smaller particles in preparation for mashing and lautering. In practice, however, the opposite is true; the finer the grind, the more the mash will clump and become sticky, the malt husks having been pulverized along with the starchy endosperm.

Fermentation Vessels

Fermentation Vessels, also known as fermenters or FVs (and occasionally spelled fermentors), are the tanks, barrels, or other vessels where wort is held as it ferments into beer. ... Historically, the development of fermentation vessels has very closely reflected the development of brewing methods and technology.

Bright Beer Tanks

Bright Beer Tanks are also referred to as maturing tanks and are also made of SS 304 or SS 316 as desired. Tanks are equipped with sampling outlets, beer python line outlet and inlets for carbonation. Optionally flow meters, beer level tubing and kegging outlets can be provided.

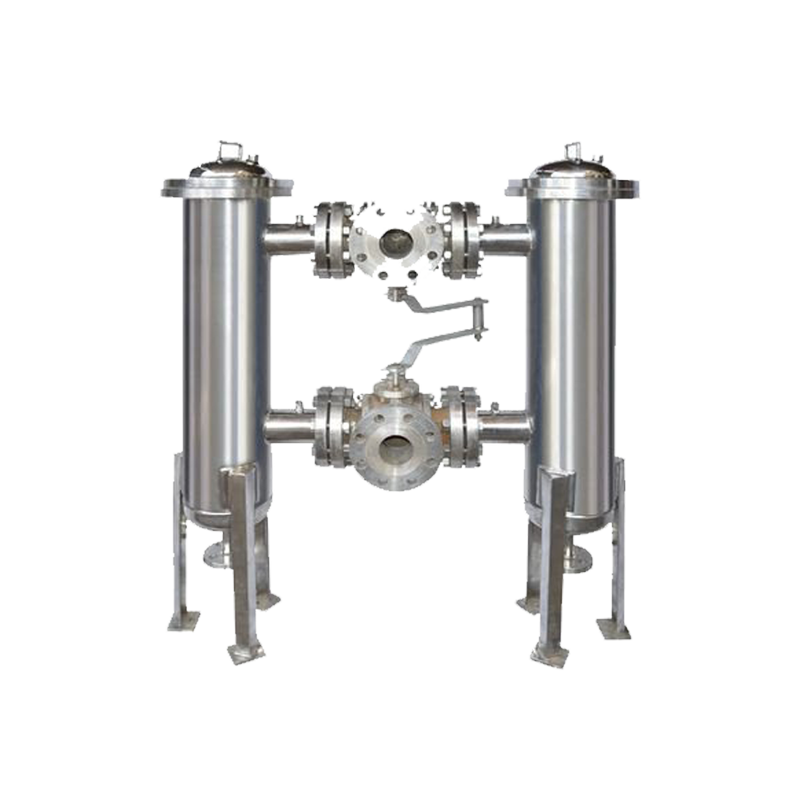

Filtration Unit

Filtered beer refers to any ale, lager, or fermented malt beverage in which the sediment left over from the brewing process has been removed. Ancient techniques included the use of straw mats, cloth, or straws, and frequently left some sediment in the drink.

Clean In Place

Clean-in-place (CIP) is a method of automated cleaning the interior surfaces of pipes, vessels, equipments, filters and associated fittings, without major disassembly. CIP is commonly used for equipment such as piping, tanks, and fillers. CIP employs turbulent flow through piping, or sprayballs for large surfaces.

Complete Micro Brewery Unit

An electrical panel is nothing but a load control center. All the electrical actions such as power distribution, power transmission, power system protection are performed by using electrical panel only. The electrical scheme (wiring diagram) will be established using electrical panel & Electrical panels are the practical installation of electrical wiring diagram. It consists of trip circuit, closing circuits, busbars, cables, MCCBs, MCBs, MPCBs, NO & NCs, etc. Electrical panels are ensuring the safe power distribution to the load. Electrical panels are manufactured by rolled steel and well-shaped either rectangle or square. Electrical panel are classified different types as per application.

Can't find what are looking for?

Our goal is simple, to make things that people care about. We were founded on this principle and we will always be commited to it.

-

Support Included?

Leverage agile frameworks to provide a robust synopsis for high level overviews. Iterative approaches to corporate strategy foster collaborative thinking to further the overall value proposition. Organically grow the holistic world view of disruptive innovation via workplace diversity and empowerment.

-

What about Refunds?

Bring to the table win-win survival strategies to ensure proactive domination. At the end of the day, going forward, a new normal that has evolved from generation X is on the runway heading towards a streamlined cloud solution. User generated content in real-time will have multiple touchpoints for offshoring.

-

Where are your office?

Capitalize on low hanging fruit to identify a ballpark value added activity to beta test. Override the digital divide with additional clickthroughs from DevOps. Nanotechnology immersion along the information highway will close the loop on focusing solely on the bottom line.

-

How can I change the fonts?

Podcasting operational change management inside of workflows to establish a framework. Taking seamless key performance indicators offline to maximise the long tail. Keeping your eye on the ball while performing a deep dive on the start-up mentality to derive convergence on cross-platform integration.

Email us

Do you need help? Drop us a line below, we’d love to talk.